Systematic Transformer Oil Filtration

- Location: Kormangala, Bangalore, Karnataka, India

In the absence of contaminants in transformer oil, the longevity and performance of transformers is boosted. Any industrial oil, besides transformer oil, tends to get polluted in course of time, due to chemical changes that might happen. The duration of the purification process also depends upon the contamination level.

In the purification process, water content is reduced in the fluids and other materials, thereby optimizing the dielectric properties of the transformer oil. The resulting improvement in insulation boosts the transformer’s performance.

Repeated operations of transformers result in oxidation of transformer oil with formation of thermal by products. These sediments cause breakdown in transformers and interrupt power supply.

The transformer oil filtration system eliminates sludge which affects the insulation material of the transformer. The temperature of oil entering the filtration system is increased in a bid to remove 60 ppm moisture and the oxygen within the moisture.

The first filter is designed to retain particles above 1mm size followed by another filter which does not allow particles beyond 50 microns size, to flow. Appropriate cartridges help this function after which the oil enters an ionic chamber where acid contents are eliminated.

The entire process is repeated few times so that the standard quality of the oil is restored. The quality of oil before and after filtration is compared, after which the process is completed. The high vacuum oil filtration system are carefully sealed to prevent any leakage and exposure to the external atmosphere. The filtration machine is equipped with appropriate controllers to keep the entire process in vigilance.

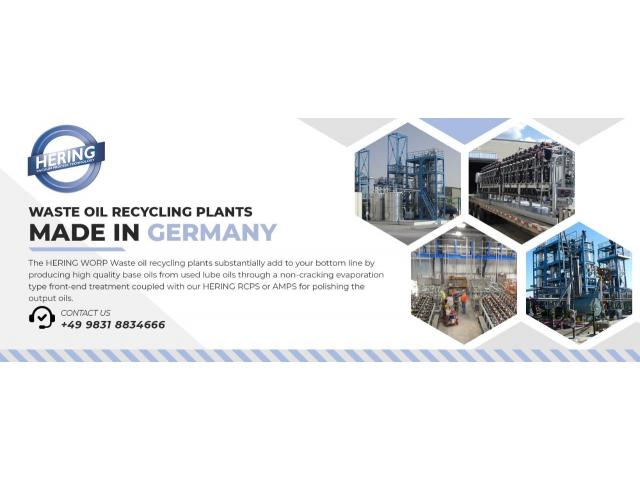

Backed by decades of experience and German engineering expertise, Hering EOK transformer oil purification offers services with benchmark technology.

Since oils are subjected to high voltages and other work pressures, EOK offers three series namely EOK Basic, EOK Standard and EOK Professional. EOK Basic serves simple operations and new transformers and oils in storage tanks. EOK Standard is applied to onsite transformer service and repairs. EOK Professional is equipped with flexibility and accommodates shortest time period to clean and is applied in a spectrum of transformer oil cleaning needs. The above mentioned classifications of transformer oil cleaning are classified based on price-performance ratio.

Hering customizes transformer oil purification plants and transformer oil degasification plants according to client needs, which removed suspended sludge materials in the oil. The oil purification plant compiles oil filters, oil pumps, oil heater, vacuum pump and degassing tank. The vacuum process mitigates boiling point by minimizing pressure. The oil heater evaporates water and other pollutants are removed through filters of varying size for different contaminants. To know more about vacuum oil filtration system visit our website. For higher levels of purifications, Hering EOK-TORS Transformer Oil Regeneration Systems would prove to be the suitable solution. They combine oil purification system with functionality of oil polishing

http://www.hering-vpt.com/products/eok-transformer-oil-purification-plants/

Related listings

-

Online fruits delivery to Solapur1500.00 US$Other Services Hubli-Dharwad (Karnataka) May 15, 2021Gift2solapur delivers provides fresh fruits delivery services all around Solapur. We offer best quality fruits and ensure safety to our customers. We also provide customized fruit gifts packed and designed as per your choice for any special events. W...

Online fruits delivery to Solapur1500.00 US$Other Services Hubli-Dharwad (Karnataka) May 15, 2021Gift2solapur delivers provides fresh fruits delivery services all around Solapur. We offer best quality fruits and ensure safety to our customers. We also provide customized fruit gifts packed and designed as per your choice for any special events. W... -

Online Fruits delivery to Mysore1500.00 US$Other Services Hubli-Dharwad (Karnataka) May 15, 2021Mysoregiftflowers delivers fresh fruits all around Mysore. We purchase the best quality fruits from best fruit shops in Mysore and ensure safety to our customers. We also provide customized fruits gift designed and packed as per your requirement. We ...

Online Fruits delivery to Mysore1500.00 US$Other Services Hubli-Dharwad (Karnataka) May 15, 2021Mysoregiftflowers delivers fresh fruits all around Mysore. We purchase the best quality fruits from best fruit shops in Mysore and ensure safety to our customers. We also provide customized fruits gift designed and packed as per your requirement. We ... -

Sweets Delivery to Solapur1500.00 ₹Other Services Hubli-Dharwad (Karnataka) May 12, 2021Gift2solapur provides sweets delivery to your home all around Solapur. We purchase sweets from best sweet shops in solapur We also offer customized gifts for any other special events. We hold the best quality and ensure safety to our customers. We ex...

Sweets Delivery to Solapur1500.00 ₹Other Services Hubli-Dharwad (Karnataka) May 12, 2021Gift2solapur provides sweets delivery to your home all around Solapur. We purchase sweets from best sweet shops in solapur We also offer customized gifts for any other special events. We hold the best quality and ensure safety to our customers. We ex...